13405527199

[Abstract] Axle end sealing device is an important component of horizontal shaft concrete mixer, which has restricted the development of mixer. The working principle, structural characteristics and failure modes of early and recent shaft end seals are discussed. It is pointed out that the service life of shaft end seals can be guaranteed and further improved in terms of technology and application.

Horizontal shaft forced concrete mixer has the advantages of strong mixing force, good mixing quality, high productivity and strong adaptability. It is suitable for the production of plasticity, semi-plasticity, dry and hard concrete and mortar. The double horizontal shaft mixer is also widely equipped in concrete mixing buildings and stations as the main engine. Because the mixing spindle is horizontally transverse, it is completely immersed in sandstone and cement materials with strong grinding ability when working, thus forming special requirements for the sealing device at the end of the shaft [1]. For a long time in the past, shaft end sealing technology has been restricting the development of horizontal shaft concrete mixer. As early as 1940, Germany Sansohofen Company (BHS) introduced a double horizontal shaft mixer, but its development is basically at a standstill due to the immature sealing technology at the end of the shaft. Until the early 1970s, due to the breakthrough of this technology, the model was developed again in German BHS company, ELBA company and Italian SICOMA company. In recent years, with the breakthrough development of shaft end sealing technology, horizontal shaft concrete mixer has been widely used.

The shaft end seal is located on the mixing shaft of the mixer, between the mixing blade (inside the cylinder body) and the supporting bearing (outside the cylinder body). Its main function is to prevent the shaft end from leaking. That is to say, the slurry of the mixer is extruded from the gap between the fixed part and the rotating part of the cylinder body to the outside of the cylinder body. Fine particles in the mud enter the clearance at the axle end and wear the fixed and rotating parts and seals. If the mud blocked the lubricating oil port, the mud hardened partially in the clearance between fixed and rotating parts, accelerating wear and tear, leading to shaft end leakage; if the mud entered and destroyed the bearing, the whole machine would not work properly.

1. Shaft end seal of early mixer

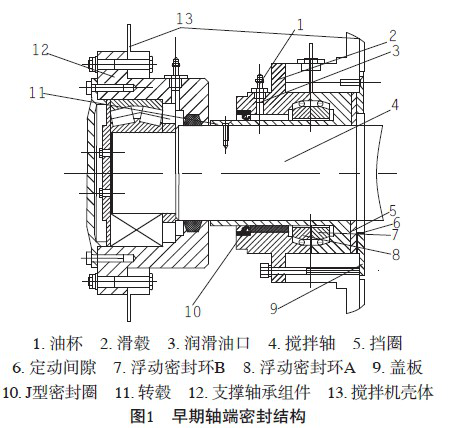

Basic Structure and Working Principle of 1.1 Axle End Seal

The basic structure of shaft end seal of early concrete mixer in China is shown in Fig. 1. Floating seal ring, hub, mixing shaft, sealing ring and sliding hub are composed of inner chamber, which is supplied with oil by a separate oil passage to keep the inner chamber under certain pressure to prevent the infiltration of cement slurry and contaminated grease; Floating seal ring, hub, flange of mixing cylinder and sliding hub are composed of floating seal ring, rotary hub, and sliding hub. The labyrinth type outer chamber is supplied with oil by a separate oil passage to maintain proper pressure on the outer chamber and prevent the invasion of cement slurry. Floating seal ring A keeps static through the friction force between O-ring and sliding hub while working. Floating seal ring A rotates with the hub through the friction force of O-ring. The hub is driven by a stirring shaft. The joint ends of the two floating seal rings produce relative motion, forming a smooth ring belt, isolating the inner and outer chambers to achieve sealing effect. The main function of J-ring is to prevent the leakage of lubricating oil in the inner cavity of floating ring. This sealing structure is also known as the open structure.

1.2 The working conditions and failure modes of the shaft end seals must satisfy the following basic conditions in order to ensure the normal operation of the shaft end seals:

(1) The oil in the inner and outer chambers should always keep proper pressure. When the mixer works, the cement slurry invades the outer labyrinth, mixes with the grease and dilutes it to consume, so it must be filled with grease before use, and constantly supplements the grease in use, and extrudes the grease through a certain pressure to offset its consumption.

(2) The joint face between two floating sealing rings should ensure a certain degree of tightness, and the contact pressure is generally 0.4-0.7 MPa. In processing and assembly, it is difficult to ensure a uniform fixed clearance, so the resistance of lubricating oil in the clearance is not equal everywhere. When the mixer works, the mud in the shell produces a certain pressure at the end of the shaft due to its own gravity and the extrusion of the mixing blade. When the pressure is greater than the minimum resistance produced by the lubricant in the gap between the mixing shaft and the cover plate, the mud will enter the gap and cause wear and tear to the mixing shaft and the cover plate; when the gap expands continuously and is subjected to wear and tear. When the mud is filled, the mud will enter the clearance between the cover and the retaining ring, and then enter the fixed clearance until the J-type oil seal is destroyed and overflowed to the hub of the slip ring, resulting in the leakage of the shaft end. In addition, if the pump oil is not sealed to the shaft end before or during use, it is easy to damage the shaft end seal.

Structure and Characteristics of 1.3 Axle End Seal

From Figure 1, we can see the following shortcomings: although the outer chamber forms a labyrinth, the opening opens directly to the mixing zone of the mixer, the pressure of the outer chamber is difficult to establish, and the cement slurry is very easy to penetrate and mix with grease, dilute and consume grease. In order to ensure the sealing effect, first of all, the clearance should be uniform in manufacturing accuracy, and secondly, a large amount of oil and grease should be continuously added to offset the consumption of oil and grease in use. However, when a large amount of oil and grease is mixed into the mixing zone of mixer, the performance of concrete will be affected to a certain extent. When producing high strength concrete and special concrete, mixing is necessary. The oil consumption of shaft end seals is strictly limited. On the premise of ensuring reliable sealing, the less oil should be mixed into the mixer, the better. In addition, because the hub is positioned by the shoulder and the sliding hub is positioned by the end plate of the mixing drum, the welding error of the distance between the two end plates of the mixing drum will directly affect the tightness of the joint end faces between the two floating sealing rings, and it is difficult to guarantee the contact pressure of 0.4-0.7 MPa. Over-tightness of assembly will lead to early wear and tear of seals and reduce service life. Over-tightness of floating seal ring joint face can not guarantee sealing effect. The shaft end seals used in early domestic mixers basically belong to the above-mentioned structural forms. Some of them enlarge the outer chamber labyrinth, some of them are tubular sleeved on the stirring shaft and connected with the stirring shaft by keys, while the sliding hub is sleeved on the hub, but the problems of the above-mentioned forms have not been solved. Some of them add gaskets between sliding hub and flange to adjust, but poor installation will cause oil leakage. The contact pressure of sealing ring joint end can only depend on the experience of installers, and the assembly quality of mixer can not be reliably guaranteed.

Improvement of Shaft End Seal of Mixer

Improvement of 2.1 Open Seal

In order to solve the above problems, various concrete mixer factories at home and abroad have taken different measures to improve the open seal structure, which effectively improves the life of the shaft end seal.

(1) One of the methods to improve the sealing structure of the shaft end. The improved sealing structure of a domestic manufacturer is shown in Fig. 2. An elastic surface sealing ring is added between the sleeve and the dust-proof cover to make the outer chamber closed and the oil and cement slurry do not contact directly, thus effectively avoiding the invasion of cement slurry. The amount of added oil can only meet the lubrication consumption between the elastic sealing ring and the hub, and the amount of oil entering the mixing zone in use is less. The sleeve is positioned by the shoulder, and the key is connected with the stirring shaft. In order to avoid the welding error of the distance between the two end plates of the mixing drum affecting the tightness of the joint end faces of the two floating sealing rings, an adjusting pad can be added between the sleeve and the dust cover. The adjusting clearance has nothing to do with the sealing chamber, which avoids the influence of oil leakage caused by improper installation on the pressure of the sealing chamber. The whole set of shaft end sealing device can be removed smoothly from the shaft end during overhaul, and the structure is simple.

(2) Improvement of Seal Structure at Axle End

The improved shaft end seal structure of a foreign manufacturer is shown in Fig. 3. A sleeve is added between the sealing device and the stirring shaft. The sliding hub and the hub are sleeved on the sleeve. After proper adjustment, the hub and the sleeve are welded. The sleeve is positioned by the shoulder and connected with the stirring shaft by the stabilizing nail. This can avoid the influence of the welding error of the distance between the two end plates of the stirring drum on the tightness of the joint end faces of the two floating sealing rings. The outer end face of the hub is aligned with the outer end face of the flange. The outer chamber labyrinth adopts single S type to increase the length of the labyrinth, which makes the gap seal easier to form, easier to process and convenient to install. An elastic surface seal ring is added between the hub and the turnplate at the outer opening of the labyrinth, which makes the outer cavity closed, effectively avoids the invasion of cement slurry, and at the same time facilitates the establishment of lubricating oil pressure. Under appropriate oil supply pressure, only the oil consumption of lubrication between elastic sealing ring and hub can be supplemented, which can greatly reduce the influence of lubricating oil mixed into mixing zone of mixer on concrete performance.

2.2 closed seal

In recent years, some manufacturers have greatly improved the main seal of the above-mentioned sealing structure. The zero gap between the pin body of rigid material and the yellow glue of flexible material is used to realize the seal, and the open seal is transformed into the closed seal. Some manufacturers have also added gas seals to auxiliary seals. Figure 4 is a schematic diagram of a company's closed shaft end seals.

2.2.1 Sealing principle in fixed clearance design a wear-resistant flexible component - yellow glue, through yellow glue to fix the steel frame on the axle head shell, the fixing ring of the axle locking device through inclined tension to press the main body of the axle locking device on the stirring shaft. The yellow glue contacts closely with the main body of the axle lock, so that the fixed clearance becomes zero. The side arm limiting ring and shaft head protecting ring are fixed on the stirring shaft through bolts and tightening bolts, and the rear side arm limiting ring is surrounded by the arm seat. The protection effect of the shaft head protecting ring and the side arm limiting ring on the shaft end can be guaranteed, so that the mud does not enter the fixed clearance between the shaft head protecting ring and the short shaft sleeve directly. The sealing principle is as follows: the first is the sealing effect of lubricating oil in the fixed clearance between the shaft head protection ring and the side arm limit ring. Before the mixer works, the fixed clearance space is filled with lubricating oil. In the work, lubricating oil is automatically injected into the fixed clearance lubricating orifice through an electric pump at a certain pressure, and extruded into the inner part of the shell through the yellow glue and the main body of the axle lock, so that the fixed clearance is always filled with lubricating oil. The second is the sealing function of the pneumatic seal ring. A ring groove is machined in the inner circle of the shaft head protection ring, which is connected with the external gas source. After the pressure gas (0.05 MPa) enters the ring groove, a gas seal ring is formed with the rotating body (the short shaft sleeve tightly sleeved on the stirring shaft). The smaller the gap between shaft head protection and sleeve is, the greater the gas seal pressure is. The pressure of the gas seal ring can push the invaded mud out of the fixed clearance and change the seal from passive blocking mud to active pushing mud out. The third way is the sealing function of the dust-proof ring. Prevent the gas from entering the main seal, so that the gas can only lead to the direction of pushing out the mud. The fourth is the seal between the yellow glue and the main body of the axle lock, which is also the main seal. Here, the fixed clearance is divided into two parts. One part is a closed working oil chamber consisting of a one-way sealing ring, the main body of the shaft lock, yellow glue and the shell of the shaft head, forming a closed seal; the other part is an open fixed clearance. The fifth is the one-way sealing ring to prevent the leakage of lubricating oil from the main body of the lubricating yellow glue and axle lock. The sixth way is the skeleton seal ring to prevent the lubricant leakage from the inner cavity of the floating seal ring.

2.2.2 failure mode

Normally, the closed seal can prevent the leakage of slurry at the shaft end more effectively, and its service life is much longer than that of the open seal. Closed shaft end seals are mainly used in larger mixers. Because of the large size of the mixer and some difficulties in processing, it is difficult to guarantee the coaxiality and perpendicularity of the end flange of the fixed shaft end seals at both ends of the shell, resulting in uneven stationary clearance, sealing of lubricants, aerodynamic seals, and yellow glue and shaft center. The seal between the axle lockers has an effect, and the mud will break through the seal. Therefore, closed seals also need timely inspection and maintenance.

Through the above analysis of shaft end seals, it can be seen that whether open or closed seals, the sealing performance is affected by the processing accuracy and assembly technology of mixing drum and shaft. Therefore, although the structure of shaft end seal has been greatly improved, there is still a lot of room for improvement in technology. The manufacturer should improve the processing accuracy and assembly technology of the mixing drum and shaft as much as possible under the premise of considering the cost performance ratio. From the use point of view, the shaft end seal should be maintained and maintained regularly, the fixed clearance should be adjusted in time, and the sealing parts should be replaced, so as to avoid the occurrence of the leakage of slurry at the shaft end and reduce the loss caused by the damage of a large number of fixed components after the leakage of slurry.