13405527199

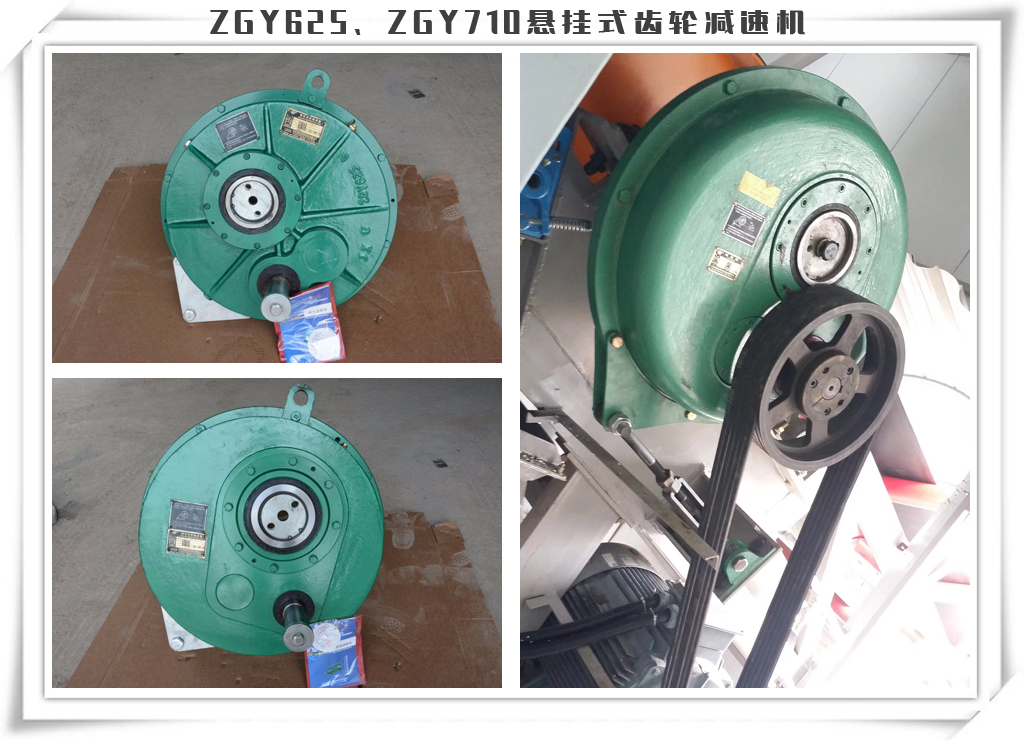

ZGY Series Axle-mounted Reducer

ZGY Series Axle-mounted Reducer

1. Overview:

ZJY/ZGY/TIT series axle-mounted reducers adopt the installation method directly suspended on the power input shaft of the matching main engine, omitting the connection accessories between them and the installation platform of the decelerator. They are widely applicable to the mechanical transmission of belt conveyor scraper conveyor, bucket elevator and other equipment, and can also be matched with other mainframes with the installation requirements.

The product is manufactured according to ZBY19009-88 standard. The main transmission parts are made of alloy steel. The gear is processed by carbon grinding point. The precision reaches grade 6 (GB10095-88). The product has the advantages of small volume, high carrying capacity, long service life, low noise and high efficiency.

2. Scope of application

The maximum speed of the high-speed end does not exceed 1500 r/mn.

The working environment is warm from 40 C to 45 C.

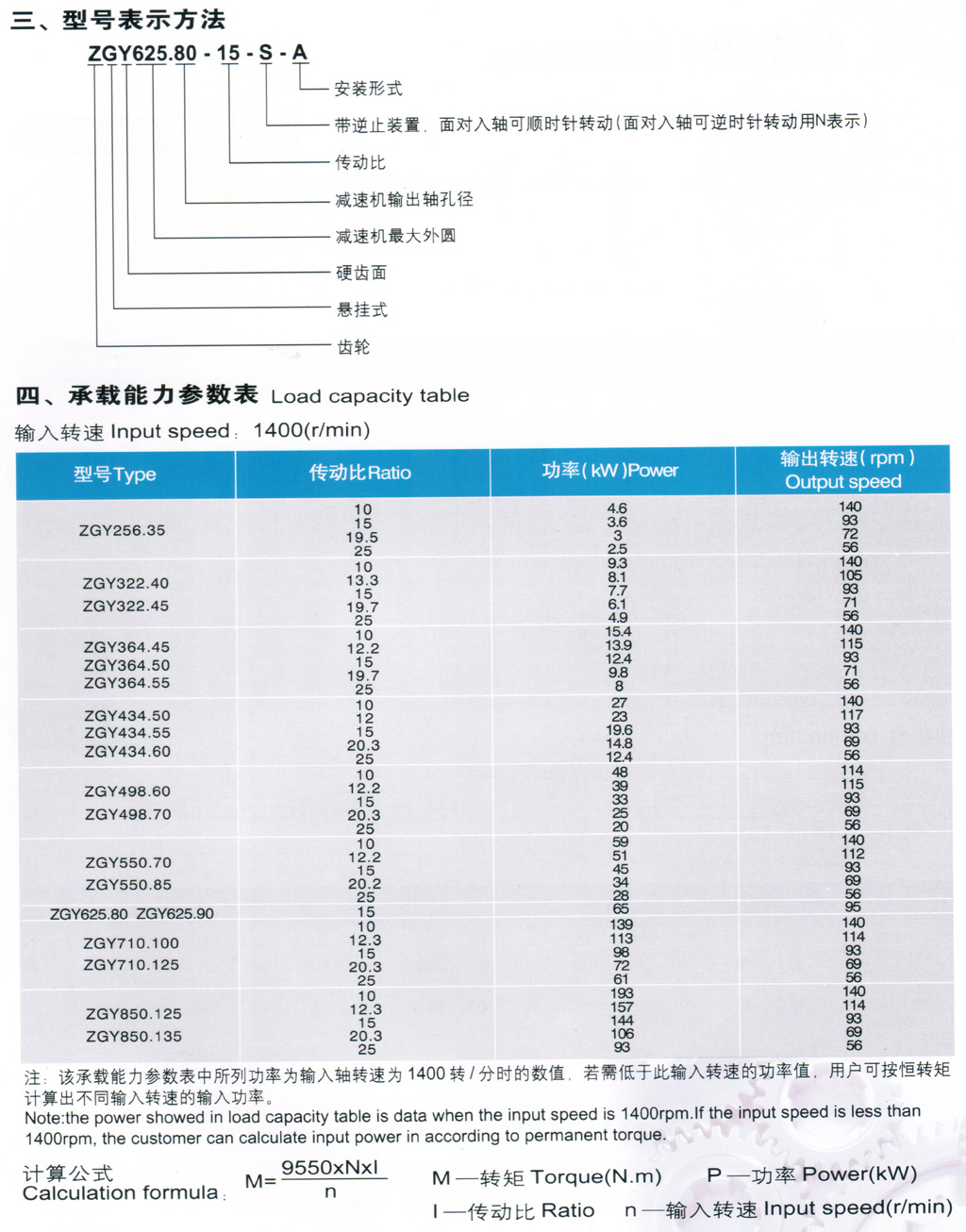

3. Product model

ZJY Series: 75, 90, 106, 125, 150, 180, 212, 250, 300, 350

ZGY Series: 498, 550, 625, 710, 850

TIT series: 4, 5, 6, 7, 8, 9, 10

ZGY suspension gear reducer is a kind of hard tooth surface reducer. It has the characteristics of small size, light weight, large carrying capacity, high efficiency, simple structure and easy installation and maintenance. The input shaft of the reducer is connected with the motor by belt pulley, and the output is connected by a single key of hollow shaft. It can replace the electric drum as belt conveyor and lifting machine. The power source of hoist is widely used in concrete mixing station, agriculture, commerce, post and telecommunication industry, food industry, tobacco industry, automobile industry, cement industry, mining industry, tourism and so on.

ZGY suspension gear reducer features:

(1) The main parameters such as center distance and nominal transmission ratio have been optimized, and the main parts and components have good interchangeability.

(2) The gears are made of high quality alloy steel by carburizing and quenching, and the hardness of the tooth surface reaches 58-62HRC.

(3) Small size, light weight, high accuracy, large carrying capacity, high efficiency, long life, high reliability, smooth transmission and low noise.

(4) Oil pool lubrication and natural cooling are generally used. When the thermal power cannot be satisfied, circulating oil lubrication or fan and cooling coil can be used for cooling.

ZGY suspension gear reducer application scope:

(1) The input speed is generally N1 < 1500r/min.

(2) The circumferential speed of gear transmission is not more than 20m/s.

(3) The working environment is - 40 - 50 C. If the temperature is lower than O C, the lubricating oil should be preheated to above 0 C before starting. The reducer can be used in both positive and negative directions.

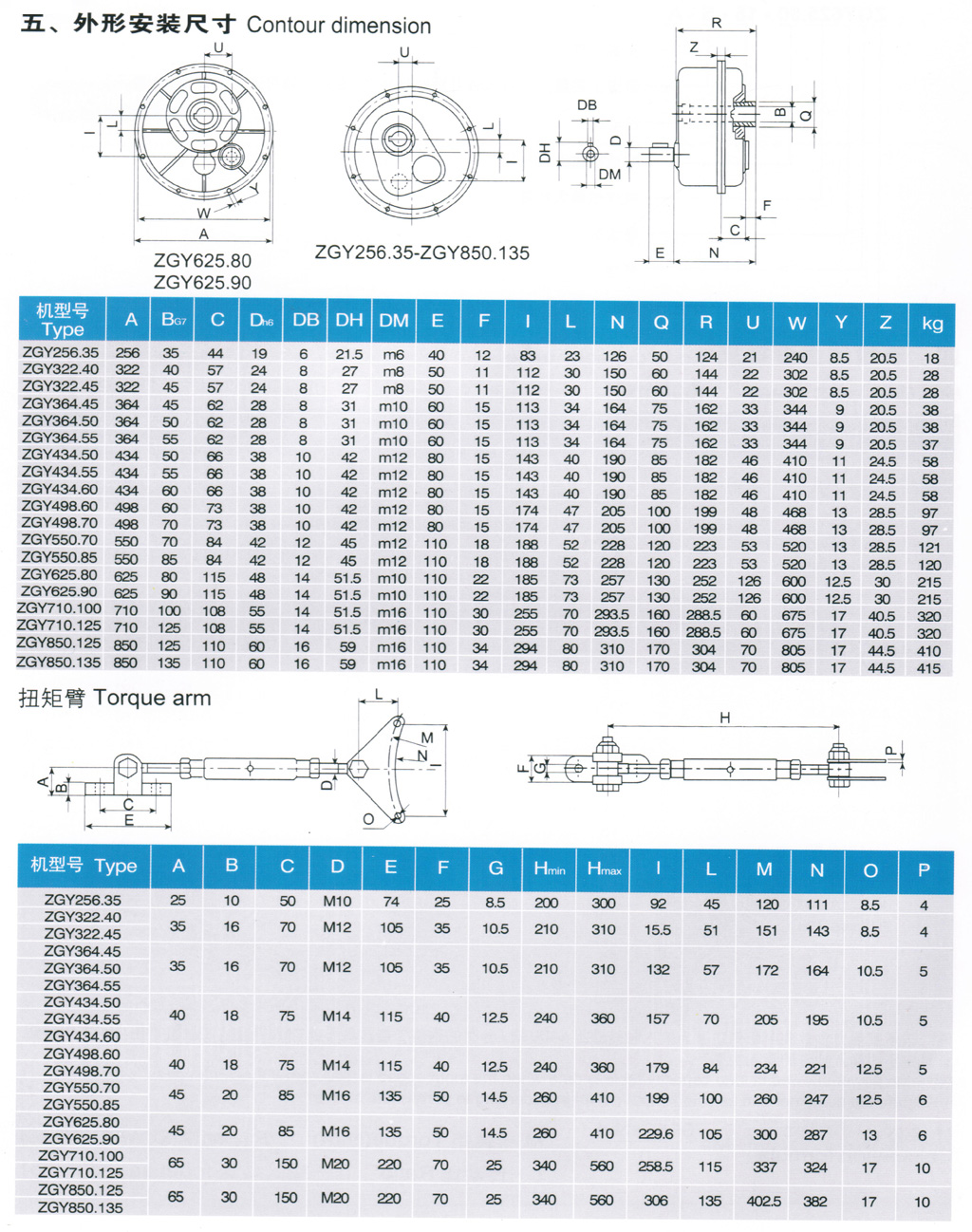

Installation and maintenance of ZGY suspension gear reducer:

1. High-speed shaft and other parts cooperate. No direct hammering is allowed. Screws can be screwed into the end of the shaft and pressed into the connecting parts.

2. The suspension reducer can be tested only after it is installed and rotated by hand without stuck.

3. Under the condition of no load, if abnormal sound, excessive heat or oil leakage are found during 2 hours of operation, stop immediately to eliminate them.

4. When installing the torsion arm, the torsion arm should be perpendicular to its fixed point and output axis, the deviation should be +10 degree, and the torsion arm should be in the state of tensile stress.

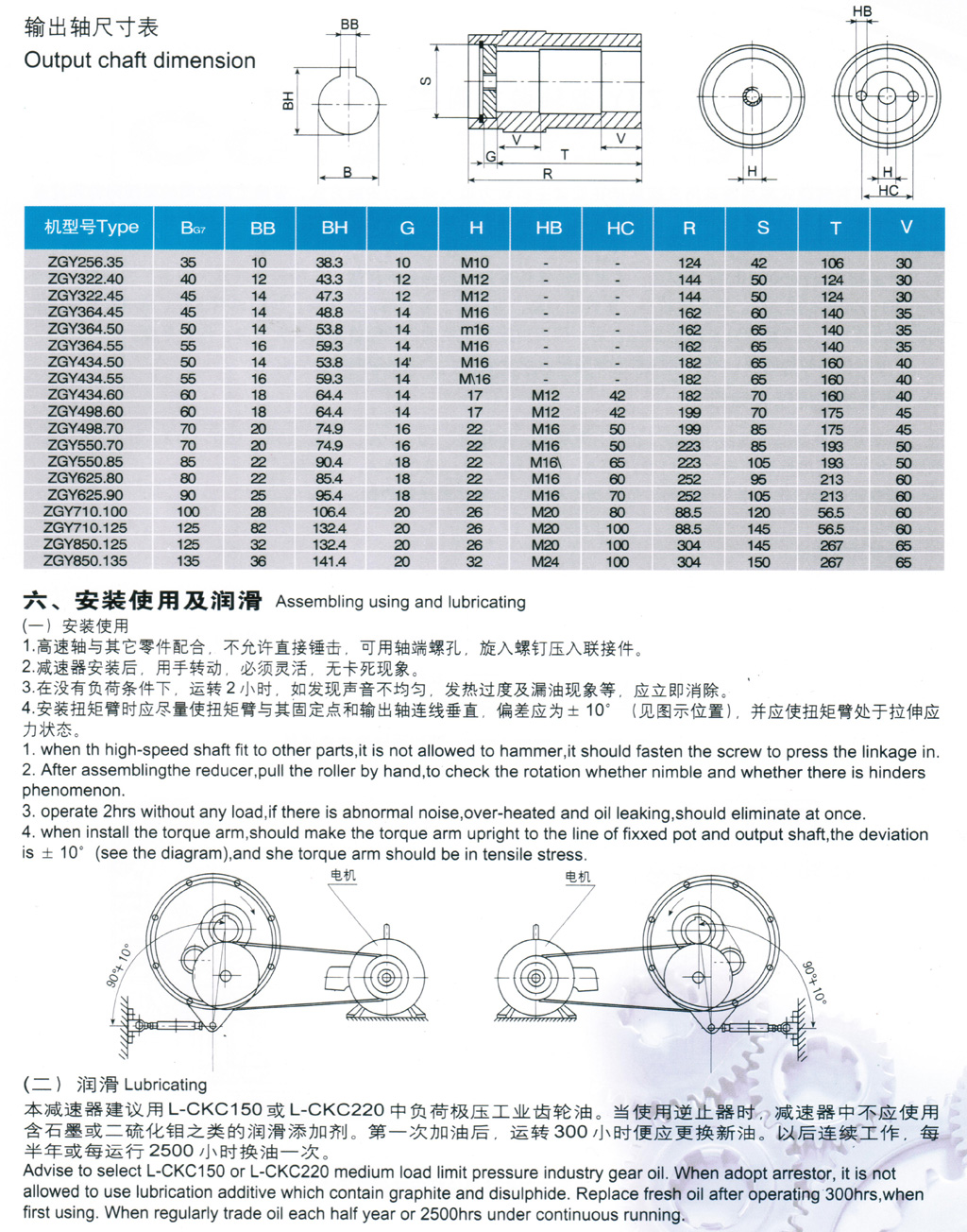

5. After 300 hours of operation, the suspension reducer should change oil for the first time and wash the gear structure with suitable detergent. Do not mix mineral oil with synthetic oil. Check oil level regularly and change oil every half year or 2500 hours.